What is Polyester Webbing Belt, and Why is it So Powerful?

Introduction

Have you ever noticed that sturdy, densely woven belt, often seen in workwear or outdoor gear? That is the Polyester Webbing Belt in its most familiar form. But did you know that this seemingly simple item is just the starting point? The material it's made from is, in fact, the foundation for numerous unsung heroes in industrial and safety applications.

This article will explore the core properties of the Polyester Webbing Belt and reveal how this very same material is engineered into critical tools like lifting slings and tie-down straps. We will uncover the versatility and reliability that make it an indispensable component in modern industry.

Chapter 1: Foundation Revealed: Understanding "Polyester Webbing" Itself

To truly appreciate the strength and versatility of products like the Polyester Webbing Belt, it is essential to first understand the material at its core: the polyester webbing itself. This foundational component is what grants the final products their remarkable characteristics.

The Core Material: Why Polyester?

Polyester, a synthetic polymer, is the engine behind this material's performance. Its molecular structure provides a unique combination of properties that make it superior to many natural fibres and even other synthetics for a wide range of applications.

- High Tensile Strength: Polyester fibres are incredibly strong for their weight, allowing webbing to withstand significant pulling forces without breaking. This is the primary reason it can be trusted for both holding up trousers and securing heavy loads.

- Low Elongation: Unlike some other materials, polyester has minimal stretch under load (typically 10-15% at break). This is a critical safety feature, especially in lifting and tie-down applications, as it prevents loads from shifting excessively once secured.

- Excellent Resistance: Polyester is highly resistant to mildew, rotting, and ultraviolet (UV) radiation from sunlight. This makes it exceptionally durable for long-term use in both indoor and outdoor environments. It also exhibits good resistance to many common chemicals.

- Abrasion Resistance: The tight, smooth weave of the webbing surface can withstand significant friction and wear against rough surfaces, contributing to its long service life.

From Webbing to Belt: The Anatomy of a Polyester Webbing Belt

A Polyester Webbing Belt serves as the perfect, everyday example of this material in action. Its structure is deceptively simple:

- The Webbing: This is the core body, a flat, woven tape of polyester yarns. The tightness and pattern of the weave determine its basic strength and feel.

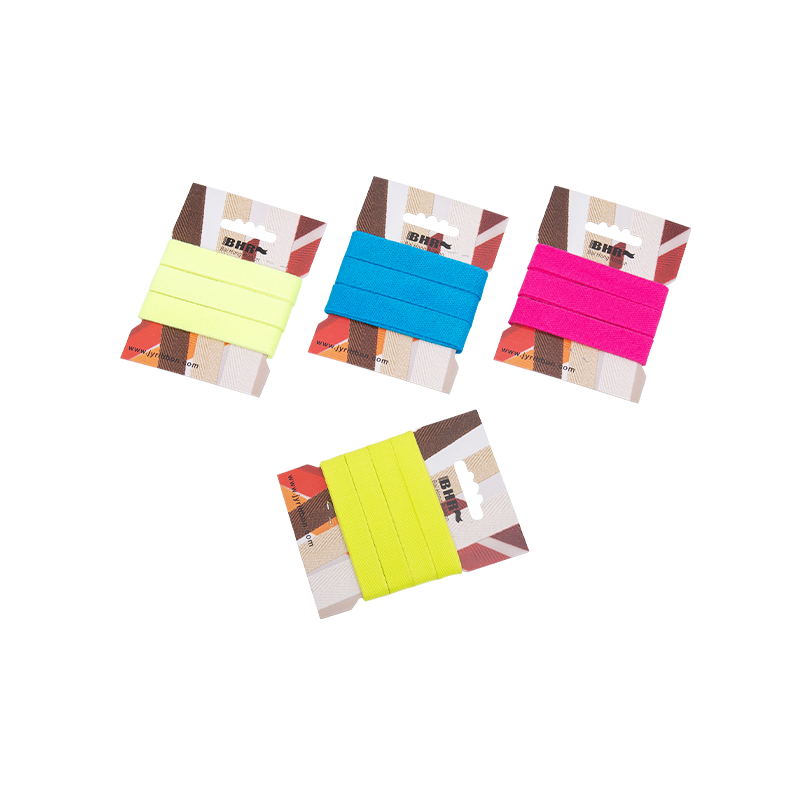

- The Dye: The material is easily dyed, allowing for a vast range of colours, from the utilitarian black or camouflage to high-visibility shades.

- The Hardware: A buckle or clip is added, but the core functionality—durability, adjustability, and strength—comes entirely from the webbing itself.

This simple construction highlights the inherent advantages of polyester webbing: it requires no complex treatments or coatings to be highly functional and durable.

How Polyester Compares: A Parameter Overview

To understand why polyester is often the material of choice, it is helpful to compare its key properties with other common webbing materials. The following table outlines these critical parameters. It's important to note that these are general ranges and can vary based on the specific weave and treatment of the webbing.

| Property | Polyester Webbing | Nylon Webbing | Polypropylene Webbing |

|---|---|---|---|

| Strength | Very High | Extremely High | Moderate |

| Elongation (Stretch) | Low (approx. 10-15%) | High (approx. 15-30%) | Low (approx. 10-20%) |

| UV & Weather Resistance | Excellent | Good (can degrade over time) | Fair to Good |

| Moisture Absorption | Very Low (~0.4%) | High (~4%, loses strength when wet) | None |

| Resistance to Mildew & Chemicals | Excellent | Very Good | Excellent |

| Abrasion Resistance | Excellent | Excellent | Good |

| Typical Applications | Lifting slings, tie-downs, utility belts | Climbing ropes, cargo nets (where shock absorption is needed) | Light-duty straps, cost-sensitive applications |

Analysis of the Comparison:

- Polyester vs. Nylon: While Nylon has a slightly higher ultimate strength, its significant stretch and susceptibility to water absorption are major drawbacks for precision lifting and long-term outdoor use. Polyester's minimal stretch and consistency in wet or dry conditions make it a more reliable and safer choice for most industrial applications.

- Polyester vs. Polypropylene: Polypropylene is lightweight and floats on water, but it is not as strong nor as UV-resistant as polyester. It is more suited for lightweight, disposable, or low-cost applications where extreme strength and longevity are not required.

In conclusion, polyester webbing does not excel in just one single area but provides the most balanced and reliable portfolio of properties overall. It is this optimal balance of high strength, low stretch, and outstanding environmental resistance that establishes polyester webbing as the foundational material for everything from a dependable Polyester Webbing Belt to the most critical lifting and tying solutions.

Chapter 2: The Evolution of Strength: The Specialized Forms of "Polyester Webbing" in Industry

The journey of polyester webbing from a simple belt to a critical industrial component is a story of engineering and adaptation. By altering its construction, finish, and assembly, the fundamental Polyester Webbing Material is transformed into specialized tools, each designed to excel in specific, demanding environments. These are the professional avatars of the humble webbing belt.

1. The Secure Lifter: Polyester Lifting Sling

When failure is not an option, the material's properties are engineered for maximum safety and reliability.

- Core Function: A Polyester Lifting Sling is designed for one primary purpose: to safely lift and move heavy loads, often in challenging industrial settings like construction, manufacturing, and shipping.

- Why Polyester is Ideal: The key characteristic of polyester that makes it perfect for lifting is its low elongation. Unlike nylon, which stretches significantly, polyester stretches very little. This minimizes load bounce and swing, allowing for precise and controlled placement of heavy machinery, steel coils, or construction modules. Its high strength and excellent abrasion resistance ensure it can withstand contact with sharp edges and heavy loads.

- Key Design Features:

- Construction: Often constructed in a seamless, looped configuration (endless) or with spliced eyes at each end.

- Reinforcement: The webbing is typically heavier and wider than that used in a standard belt.

- Protection: Many slings incorporate additional protective features, such as wear pads or coated sections, in high-friction areas.

- Identification: They are rigorously tested and come with a permanent label stating their Working Load Limit (WLL), a critical safety requirement.

2. The Road Warrior: Polyester Tie-Down Strap

Where the Polyester Lifting Sling moves loads vertically, the Polyester Tie-Down Strap secures them for horizontal travel.

- Core Function: To securely fasten cargo to trailers, flatbed trucks, and in shipping containers during transport, preventing movement that could lead to accidents or damage.

- Why Polyester is Ideal: For tie-downs, the combination of high tensile strength and low stretch is, again, paramount. A strap that stretches excessively during transit can loosen as the cargo settles, leading to a dangerous shift in weight. Polyester maintains its tension effectively. Its resistance to UV degradation and moisture is also crucial for straps constantly exposed to sun, rain, and road chemicals.

- Key Design Features:

- Assembly: Comprises the polyester webbing body combined with end fittings, which are most often ratchet buckles, cam buckles, or end hooks.

- Mechanism: The ratchet buckle provides a mechanical advantage, allowing the user to apply extremely high tension to the webbing, far beyond what is possible with a simple belt buckle.

3. The Universal Workhorse: Webbing Sling

The term Webbing Sling is a broader category that often overlaps with the Polyester Lifting Sling. However, it specifically highlights the type of material (woven webbing) as opposed to wire rope or chain.

- Core Function: A general-purpose sling for lifting, hoisting, and securing, valued for its versatility and its ability to protect delicate loads from scratches.

- Why Polyester is the Preferred Material: When a Webbing Sling is made from polyester, it inherits all the advantages discussed. It is the material of choice for most synthetic sling applications due to its balanced property profile. It is lighter and easier to handle than chain or wire rope and does not kink or corrode.

- Key Design Features: Available in various configurations—endless, twisted, eye-and-eye—to suit different lifting geometries.

Comparative Analysis: Choosing the Right Tool for the Job

The following table summarizes how these specialized products, all derived from the same core material, are differentiated by their design and application.

| Feature | Polyester Lifting Sling | Polyester Tie-Down Strap | Webbing Sling (Polyester) |

|---|---|---|---|

| Primary Application | Vertical Lifting of heavy loads. | Horizontal Securing of cargo during transport. | General Lifting & Rigging (vertical & choked). |

| Key Performance Focus | Safety, Precision, Load Protection. | Maintaining Tension, Weather Resistance. | Versatility, Load Protection, Ease of Use. |

| Typical Hardware/Ends | Spliced loops, sometimes with metal fittings. | Ratchet or Cam Buckles, J-hooks, S-hooks. | Spliced eyes (eye-and-eye), endless loops. |

| Governing Standards | Rigorous, often defined by international standards (e.g., ASME, EN). | Regulated by transportation authorities. | Often follows the same standards as Lifting Slings. |

| Critical Material Property | Extremely Low Elongation, High Strength. | High Strength, Low Stretch, UV Stability. | Abrasion Resistance, Strength, Flexibility. |

| Load Dynamics | Static or slow-moving loads. | Dynamic loads subject to vibration and G-forces. | Primarily static or controlled movement. |

Synthesis of the Evolution:

This evolution from a basic belt to specialized industrial tools demonstrates a critical principle: application dictates design.

- A Polyester Webbing Belt is optimized for personal adjustability, comfort, and daily wear.

- A Polyester Lifting Sling is engineered for ultimate, fail-safe load control in critical lifts.

- A Polyester Tie-Down Strap is built to combat the dynamic forces of the open road.

- The term Webbing Sling specifies the material form, with polyester being the premium choice.

- And it all begins with the raw, engineered fabric: Polyester Webbing Strap and Polyester Webbing Material, which serve as the blank canvas for this entire family of high-performance products.

Understanding this evolution allows users to move beyond seeing these as separate items and to recognize them as a family of solutions, all powered by the unmatched balance of properties inherent to polyester webbing.

Chapter 3: How to Select the Right "Polyester Webbing" Product for You?

Understanding the properties and specializations of polyester webbing is the first step. The next, more practical step, is applying this knowledge to select the perfect product for your specific need. Making the correct choice is not just about efficiency; it is fundamentally about safety and achieving the desired outcome. This guide will help you navigate the selection process.

The most critical factor is to match the product to your primary application. The following flowchart provides a visual guide to narrow down your options based on what you intend to do.

The Universal Checklist: Key Parameters to Evaluate

Regardless of which product you choose from the chart, the following parameters must be verified before use. This checklist applies to everything from a Polyester Lifting Sling to a simple Polyester Webbing Belt.

- Width and Thickness:

- Why it matters: The wider and thicker the webbing, the greater its load-bearing capacity and abrasion resistance. A narrow belt is fine for a pocket knife; a wide sling is essential for a steel beam.

- What to look for: Always check the product specifications for the exact width.

- Working Load Limit (WLL) / Breaking Strength:

- Why it matters: This is the most critical safety parameter. The Working Load Limit (WLL) is the maximum allowed load during routine use. It is a fraction of the ultimate Breaking Strength (the point at which it snaps). Never, ever exceed the WLL.

- What to look for: The WLL must be permanently marked on the product, especially on lifting slings and straps. A clear label is a sign of a reputable manufacturer.

- Material and Construction:

- Why it matters: Confirm the material is 100% polyester. Check the weave for consistency and tightness. Look for reinforced edges, which prevent fraying and increase longevity.

- What to look for: A uniform, dense weave with no visible flaws or weak spots.

Parameter Comparison for Product Selection

The table below illustrates how these key parameters translate across different product types, emphasizing why a one-size-fits-all approach does not work.

| Parameter | Polyester Webbing Belt | Polyester Tie-Down Strap | Polyester Lifting Sling / Webbing Sling |

|---|---|---|---|

| Primary Application | Personal use, fashion, light-duty carry. | Securing cargo on trucks, trailers. | Vertical lifting of heavy industrial loads. |

| Typical Width Range | 1.5" (38mm) to 2" (50mm) | 1" (25mm) to 4" (100mm) | 1" (25mm) to 12" (300mm) + |

| Critical Focus | Adjustability, Comfort, Aesthetics. | Tension Maintenance, UV Resistance, Buckle Strength. | Safety Factor, Low Elongation, Certified WLL. |

| Working Load Limit (WLL) | Not typically rated. For light duty only. | Clearly stated (e.g., 1,500 lbs). | Stated and legally mandated. Very high (e.g., 5,000 to 50,000+ lbs). |

| Safety & Certification | No formal certification. | Should meet transportation standards. | Must comply with strict industry standards (e.g., ASME B30.9, EN1492). |

| Hardware Inspection | Buckle durability and stitch integrity. | Ratchet mechanism, hook integrity. | Splicing quality, eyelet integrity. |

Putting It All Together: A Summary Guide

- For Personal, Everyday Use: A Polyester Webbing Belt is sufficient. Your choice will be based on width, color, and buckle style. It is not a tool for lifting or securing heavy cargo.

- For Securing Cargo on a Road Trip or Truck: You need a Polyester Tie-Down Strap. Select the width and WLL based on the weight of your load. Always inspect the ratchet buckle and hooks for damage before each use.

- For Lifting and Moving Heavy Equipment or Materials: You must use a certified Polyester Lifting Sling or Webbing Sling. This is non-negotiable. Choose the configuration (endless, eye-and-eye) and WLL based on the lift plan. Ensure it has a legible, permanent identification tag.

- For DIY Projects or Custom Manufacturing: Your starting point is the Polyester Webbing Strap or Polyester Webbing Material itself. Your selection will be driven by the required width, strength, and color for your specific project, ensuring the raw material's specifications match the intended function of the final product.

By systematically defining your need and then verifying the product's specifications against that need, you can harness the full potential of polyester webbing safely and effectively.

Conclusion

The journey from a simple Polyester Webbing Belt to the high-strength industrial applications of Polyester Lifting Slings and Tie-Down Straps is a powerful testament to the remarkable versatility and engineering value of the core material: polyester webbing. This exploration reveals a fundamental truth: the inherent properties of the base material dictate the performance, safety, and suitability of the final product across a vast spectrum of uses.

Throughout this article, we have deconstructed the elements that make polyester webbing a material of choice. Its optimal balance of high tensile strength, low elongation, superior environmental resistance, and exceptional durability creates a foundation upon which specialized and reliable products are built. The evolution of this material into its various professional forms is not a mere change in shape or name, but a targeted application of these core properties to meet specific, demanding challenges.

Synthesis of Key Differentiators

The following table provides a final, consolidated overview that encapsulates the distinct roles and critical considerations for each product form, demonstrating how a shared material foundation supports specialized functions.

| Aspect | Polyester Webbing Belt | Polyester Tie-Down Strap | Polyester Lifting Sling |

|---|---|---|---|

| Primary Role | Personal Utility & Apparel | Cargo Securement & Logistics | Industrial Lifting & Rigging |

| Core Driver | Convenience, Adjustability, Comfort. | Tension Maintenance & Dynamic Load Security. | Precision, Safety & Load Integrity. |

| Critical Property | Flexibility, Aesthetics, Durability. | Low Elongation, UV Resistance, Tensile Strength. | Extremely Low Elongation, Certified Strength, Abrasion Resistance. |

| Safety Focus | General durability and buckle integrity. | Working Load Limit (WLL), hardware inspection. | Mandatory WLL Compliance, Regular Certification, Rigorous Inspection. |

| End-User Mindset | "Is it durable and fit for purpose?" | "Is this strap rated to secure my specific load safely?" | "Is this sling certified, inspected, and suitable for this exact lift?" |

The Unifying Principle: Informed Selection

The critical takeaway is that an informed selection process is paramount. Choosing the correct product is no longer just about finding something that "looks strong." It is about understanding the fundamental demands of the application:

- For any task involving vertical lifting, the non-negotiable requirement for safety and control mandates the use of a certified Polyester Lifting Sling, leveraging its minimal stretch and proven strength.

- For securing loads in transit, the dynamic forces and environmental exposure require the steadfast performance of a Polyester Tie-Down Strap, whose ability to maintain tension is vital.

- Even for casual use, the reliability of a Polyester Webbing Belt stems from the same material science that powers its industrial counterparts.

In essence, the story of polyester webbing is one of engineered adaptation. By recognizing the direct link between the material's innate characteristics and the performance of the final product, users—from professionals to hobbyists—can make decisions that are not only effective but, most importantly, safe. This knowledge transforms the selection from a simple purchase into a strategic application of material science, ensuring that the right tool, born from the right material, is used for the right job.

Frequently Asked Questions (FAQ)

1. Q: Can I use a heavy-duty Polyester Webbing Belt as a substitute for a proper Tie-Down Strap to secure items on a trailer?

A: No, this is not safe and strongly discouraged. While a Polyester Webbing Belt is durable, it is not designed or rated for the dynamic forces and high tension of cargo securement. A proper Polyester Tie-Down Strap is equipped with a ratchet or cam buckle specifically engineered to apply and withstand extreme tension, and it has a defined Working Load Limit (WLL). Using a belt for this purpose creates a significant safety risk due to potential failure.

2. Q: What is the single most important factor to check when using a Polyester Lifting Sling?

A: The most critical factor is the Working Load Limit (WLL) and ensuring the load does not exceed it. A Polyester Lifting Sling must have a permanent, legible tag stating its WLL. Furthermore, you must inspect the sling for any signs of damage—such as cuts, abrasion, broken stitches, or chemical burns—before every single use. Safety in lifting operations is paramount and non-negotiable.

3. Q: I need a webbing for an outdoor project that will be exposed to sun and rain. Is polyester the best choice?

A: Yes, polyester is an excellent choice for outdoor use. Its inherent resistance to ultraviolet (UV) radiation and moisture (it does not rot or mildew) makes it far superior to materials like nylon, which degrades in sunlight, and polypropylene, which has lower overall strength and UV resistance. The longevity and maintained strength of polyester webbing in harsh weather conditions are key reasons it is specified for both Tie-Down Straps and Lifting Slings used outdoors.

News categories

- Quick Links

- Contact Information

-

-

NO.137-1 Chenglu Road, Huashi Town, Jiangyin City214421, Jiangsu, China

NO.137-1 Chenglu Road, Huashi Town, Jiangyin City214421, Jiangsu, China -

+86 138-0616-9220

+86 138-0616-9220 -

Lhbhzd@126.com

Lhbhzd@126.com

bh@jyribbon.com

sales2@jyribbon.com

-

- Mobile QR Code

English

English  русский

русский  Español

Español