What Are Fashion Personalized Shoelaces?

Introduction: More Than Just Function – The Rise of Personalized Fashion

In the dynamic world of fashion and self-expression, even the most utilitarian accessories are being reimagined as canvases for individuality. Enter the era of Fashion Personalized Shoelaces—a vibrant trend transforming a simple functional component into a powerful statement piece. Gone are the days when shoelaces were merely an afterthought, chosen only for length and color. Today, they are at the forefront of personal style, brand marketing, and commemorative gifting. This shift is driven by several key cultural and commercial forces. The explosive growth of global sneaker culture has elevated footwear to collectible status, creating demand for unique accessories that allow enthusiasts to further customize their prized possessions. Simultaneously, the desire for unique wedding details and cohesive bridal party gifts has opened a niche for elegant, sentimental customization. Furthermore, brands are continuously seeking innovative, wearable mediums for marketing, making custom shoelaces an ideal mobile billboard. This convergence of personal expression, emotional significance, and commercial utility has propelled Fashion Personalized Shoelaces from a niche novelty to a mainstream accessory category, appealing to consumers, corporations, and creatives alike who seek to leave a distinct, personal imprint on every step.

- From Utility to Identity: Shoelaces have evolved from purely functional items to key fashion accessories.

- Sneaker Culture Catalyst: The collector and customization mindset in sneakerheads drives demand for unique laces.

- Sentimental Value: Used in life’s milestones, such as weddings, graduations, and team events, for lasting memories.

- Brand Marketing Tool: An effective and affordable medium for logos and messaging on the move.

The Core of Customization: Types and Technologies for Personal Shoelaces

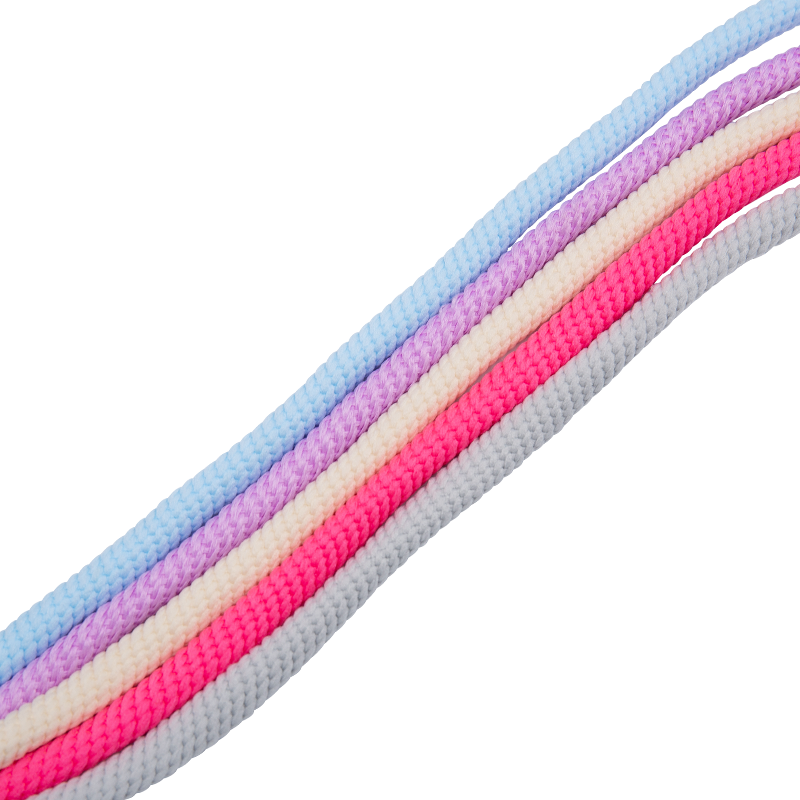

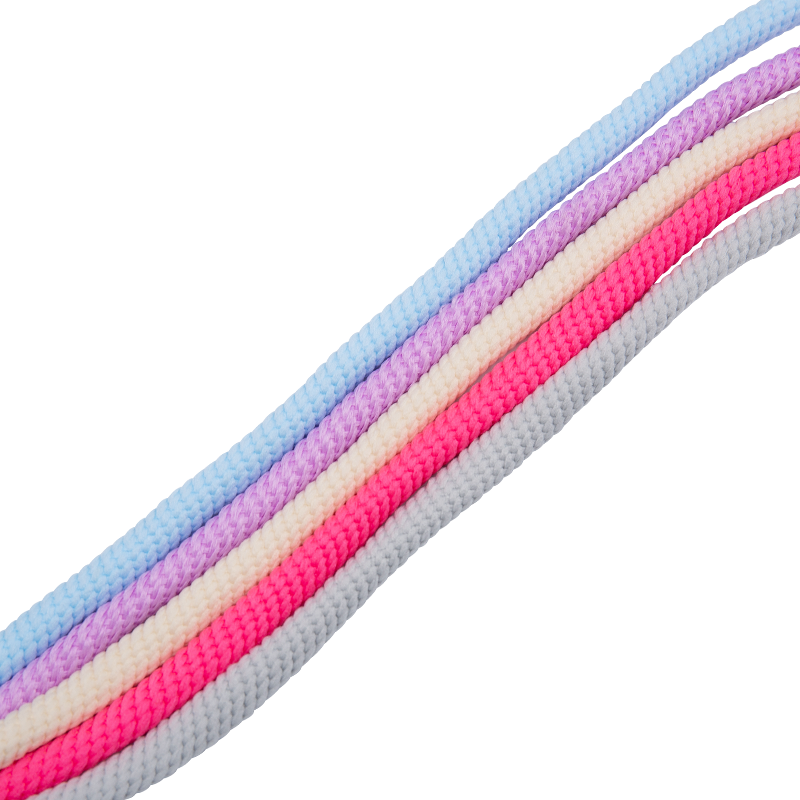

The creation of compelling Fashion Personalized Shoelaces hinges on a synergy between innovative materials and advanced manufacturing techniques. The foundation is the material itself. While traditional flat or round cotton and polyester shoelaces remain popular for their classic look and durability, modern trends embrace specialized fabrics. Colorful elastic personalized shoelaces, for instance, have gained massive popularity for their ease of use, snug fit, and vibrant, often multi-colored patterns. They are particularly favored in casual and athletic wear for their comfort and stretch. Beyond material, the personalization technology defines the final product's aesthetic and quality. Digital printing allows for photorealistic images, intricate patterns, and gradient colors directly onto the lace fabric, offering limitless creative possibilities. For a more tactile, premium feel, precision embroidery is used to stitch names, dates, or logos onto the lace, creating a raised, durable finish that withstands wear. The most integrated and high-end technique is computer-controlled Jacquard weaving, where the design, text (like a name or team motto), and pattern are woven directly into the lace structure itself during production, resulting in a seamless, professional, and exceptionally durable product. The choice of technique depends on the design complexity, order volume, desired hand-feel, and budget.

| Personalization Technique | Best For | Key Characteristics |

| Digital Printing | Photographs, complex graphics, gradients, low-to-medium volume orders. | Vibrant colors, no design limits, cost-effective for complex art, feel depends on print coating. |

| Embroidery | Logos, names, dates, text. Ideal for embroidered logo shoelaces for brands. | Textured, raised finish, very durable and premium look, higher cost, limited by stitch density. |

| Jacquard Weaving | Integrated patterns, text, stripes. Perfect for personalized shoelaces for sports teams. | Design is part of the lace structure, extremely durable, clean edges on text, efficient for large runs. |

Key Applications and Target Markets

The versatility of Fashion Personalized Shoelaces allows them to serve diverse markets, each with unique motivations. In the realm of sports and community, personalized shoelaces for sports teams are a powerful tool for building unity and displaying pride. Whether for a local soccer club, a corporate running team, or an e-sports organization, laces featuring team colors, mascots, or player numbers foster a strong collective identity. Moving to individual expression, custom name shoelaces for sneakers represent the peak of personal branding in streetwear. They allow individuals to literally wear their identity, turning a mass-produced sneaker into a one-of-a-kind item. This application is hugely popular for gifts, within fan communities, and as a form of self-expression among youth culture. For life’s celebratory moments, personalized wedding shoelaces for bridal party have emerged as a cherished detail. Brides, grooms, and their attendants can wear laces embroidered with the wedding date, their names, or a romantic phrase, adding a subtle yet meaningful personal touch to their attire and creating a lasting keepsake. Commercially, embroidered logo shoelaces for brands are a savvy marketing investment. They are used in corporate merchandise, as promotional giveaways, in retail product packaging, or as part of special collaboration releases, ensuring brand visibility in an organic, wearable format.

- Sports & Teams: Builds camaraderie and visible team identity for athletes and fans.

- Individual Fashion: Enables unique self-expression and customization of footwear collections.

- Weddings & Events: Adds sentimental, personalized details to special occasion attire.

- Corporate & Branding: Serves as innovative, practical merchandise and promotional material.

From Design to Delivery: Working with a Professional Manufacturer

Turning a concept for Fashion Personalized Shoelaces into a tangible, high-quality product requires a partnership with a capable and experienced manufacturer. This collaboration is crucial for navigating material selection, technical feasibility, quality assurance, and scalable production. A specialist factory brings deep expertise in textile weaving, dyeing processes, and the specific requirements of footwear accessories. The journey typically follows a structured path. It begins with a design consultation to discuss your vision, whether it's for vibrant colorful elastic personalized shoelaces or elegant personalized wedding shoelaces for bridal party. The manufacturer will advise on the best material and customization technique (print, embroidery, Jacquard) to achieve the desired look, feel, and durability within budget. Next, prototype samples are created for your approval, ensuring colors, dimensions, and personalization details are perfect. Upon sample sign-off, production commences using advanced machinery like computerized Jacquard looms and precision embroidery machines. Throughout manufacturing, rigorous quality control checks are conducted—from verifying color fastness and tensile strength to inspecting each personalized detail. Finally, the finished products are prepared for efficient global logistics. Partnering with a manufacturer that controls this entire process, especially one with in-house R&D and testing, is the key to receiving a product that is not only creatively satisfying but also consistently reliable and safe.

- Technical Consultation: Expert guidance on material and method selection for your design goals.

- Prototype Sampling: Physical samples ensure the design meets expectations before full production.

- Advanced Production: Utilization of modern looms and printers for precision and efficiency.

- Comprehensive QC: Multiple checkpoints for material integrity, print/weave accuracy, and safety.

- Integrated Supply Chain: Smooth handling from production to packing and international shipping.

Why Choose Baihong Webbing as Your Creative Partner?

Selecting the right manufacturing partner is pivotal to the success of your custom shoelace project. You need a collaborator with proven expertise, a commitment to quality, and the capability to scale from prototype to mass production. With a foundation built over two decades, we have established ourselves as a leader in specialized woven textiles. Since our establishment in 2002, we have dedicated ourselves to providing high-quality, safe, and reliable products for the global garment and footwear industries. Our focus on innovation is demonstrated by our in-house research and development team and dedicated testing laboratory, which ensure every product—from standard webbing to intricate Fashion Personalized Shoelaces—meets the highest standards of performance and safety. This commitment is validated by our 100% Oeko-Tex certification, guaranteeing our textiles are free from harmful substances. Our production facility is equipped with state-of-the-art machinery, including Jacquard woven machines and narrow-fabric needle looms, allowing us to execute complex custom weaves and prints with precision. Strategically located with efficient access to major export ports, we are adept at managing logistics for clients worldwide, from Europe and America to Japan. We believe in a partnership approach, taking the time to understand and solve each client's unique challenges, whether you are a startup creating your first custom name shoelaces for sneakers or a large brand commissioning embroidered logo shoelaces for brands. Our goal is to be your trusted, creative partner in bringing unique personalized shoelace concepts to life.

| Our Advantage | How It Benefits Your Project |

| 20+ Years of Expertise | Deep knowledge of materials, weaving techniques, and footwear industry standards. |

| In-House R&D & Testing Lab | Ensures product innovation, durability, and compliance with safety standards (Oeko-Tex). |

| Advanced Manufacturing Technology | Enables high-precision customization via Jacquard weaving, embroidery, and printing. |

| Global Export Experience | Reliable, efficient supply chain and logistics for smooth delivery to international markets. |

| Customer-Centric Service | Dedicated support through every step, from design consultation to final delivery. |

Your Guide to Creating Successful Custom Shoelaces

Embarking on a custom shoelace project is an exciting venture. To ensure success, start with clear design goals. Consider your audience: Are you creating a bold fashion statement, a sentimental gift, or professional branded merchandise? For text-based designs like names or dates, choose legible fonts and ensure the size is appropriate for the lace width. For logos or complex graphics, provide high-resolution vector files to your manufacturer for the cleanest reproduction. Before contacting a manufacturer, prepare key information: your desired material (elastic, cotton, polyester), target dimensions (length, width), the personalization technique preferred, color codes (PANTONE, if available), and an estimated quantity. This preparation enables a productive initial consultation and leads to more accurate quotes and prototypes. Remember, an experienced manufacturer is your ally—leverage their expertise to navigate technical constraints and optimize your design for manufacturability and impact.

FAQ

What is the minimum order quantity (MOQ) for personalized shoelaces?

The MOQ for Fashion Personalized Shoelaces varies significantly depending on the customization technique and the manufacturer's capabilities. For digitally printed or embroidered designs, MOQs can be relatively low, sometimes starting at a few hundred pairs, as these methods are adaptable. For techniques like Jacquard weaving, where the design is integrated into the loom setup, the MOQ is typically higher, often starting at several thousand pairs, due to the more involved and fixed setup process. It's always best to discuss your project directly with a manufacturer, as some, especially those with flexible production lines, may offer lower MOQs to accommodate startups or special event orders like personalized wedding shoelaces for bridal party.

What are the main differences between printed and embroidered personalized shoelaces?

Printed and embroidered shoelaces offer distinct looks and feels. Printed laces, created through sublimation or digital printing, allow for full-color graphics, photographs, and intricate patterns with no limit on colors. The design lies flat on the lace surface. Embroidered laces, ideal for embroidered logo shoelaces for brands, use threads stitched onto the base material. This creates a textured, raised, and tactile finish that is generally more durable and premium-looking. However, embroidery has limitations on fine detail and gradient colors compared to printing. The choice depends on your design complexity, desired aesthetic (flat vs. textured), budget, and emphasis on durability.

How durable are elastic personalized shoelaces compared to traditional ones?

High-quality colorful elastic personalized shoelaces are engineered for durability comparable to traditional laces, but their performance differs. The elastic core (often spandex/Lycra wrapped in polyester) provides excellent stretch and recovery, reducing stress on the fibers during tying and wear. They are highly resistant to breaking from tension. However, their edges might be more susceptible to abrasion against rough eyelets over very long periods compared to a tightly woven flat polyester lace. For most casual and athletic applications, modern elastic laces are extremely durable. The key is sourcing from a manufacturer that uses premium elastic fibers and robust weaving or knitting techniques to ensure the personalization (print or pattern) does not compromise the integrity of the stretch material.

Can you create shoelaces with complex multi-color logos?

Yes, complex multi-color logos can be expertly reproduced on Fashion Personalized Shoelaces. The best technique depends on the logo detail. Digital printing is unmatched for reproducing logos with gradients, shadows, or many colors photorealistically. For a more classic and durable finish, precision embroidery can handle multi-color logos, though extremely fine detail may be simplified. The most seamless method for woven logos is Jacquard weaving, which can incorporate multiple colored yarns directly into the lace structure, creating a crisp, durable logo that is part of the fabric itself. This is a popular choice for personalized shoelaces for sports teams with detailed crests. Providing a high-resolution vector file of your logo ensures the manufacturer can advise on the optimal and most cost-effective production method.

What is the typical production lead time for a custom order?

The lead time for custom Fashion Personalized Shoelaces typically ranges from 4 to 8 weeks from final design approval and deposit receipt. This timeline encompasses several stages: sourcing specific materials (especially for custom-dyed colors), setting up the looms or printing/embroidery machines for your unique design, producing approval samples (if a second round is needed), conducting full mass production, and performing final quality inspections. Simpler orders, like standard custom name shoelaces for sneakers using existing materials, may be on the shorter end, while complex Jacquard weaves or new material development will require more time. A reliable manufacturer will always provide a detailed production schedule upon order confirmation.

News categories

- Quick Links

- Contact Information

-

-

NO.137-1 Chenglu Road, Huashi Town, Jiangyin City214421, Jiangsu, China

NO.137-1 Chenglu Road, Huashi Town, Jiangyin City214421, Jiangsu, China -

+86 138-0616-9220

+86 138-0616-9220 -

Lhbhzd@126.com

Lhbhzd@126.com

bh@jyribbon.com

sales2@jyribbon.com

-

- Mobile QR Code

English

English  русский

русский  Español

Español