We have our own R&D team and testing lab to ensure the quality of the products. In recent years, our company has introduced a series of advanced equipment including Narrow-fabric needle loom ,Jacquard woven machine,pre-shrinking machine,warping machine to improve our production. In addition, we have obtained 100% Okeo-tex certificates. Our products are in line with international standards,and are mainly exported to Europe, America, Japan and other areas around the world.

To maintain excellent service, We’ll take time to deal with each issue, no matter how mundane it may appear to you. Baihong continually strive to be leaders in webbing industry.

-

In the dynamic world of textile manufacturing and fashion design, the demand for materials that combine aesthetic versatility with structural integrit...

READ MORE -

Introduction: More Than Just Function – The Rise of Personalized Fashion In the dynamic world of fashion and self-expression, even the most utilitaria...

READ MORE -

In the rapidly evolving landscape of fashion accessories, the convergence of individual expression and environmental responsibility has become a centr...

READ MORE -

In the realm of industrial textiles and load-bearing applications, the margin for error is virtually zero. Whether utilized in cargo restraint, safety...

READ MORE

How to ensure the accuracy and consistency of the pattern during the production of jacquard stretch webbing?

1. Material selection and process optimization

The accuracy and consistency of the pattern of personalized Jacquard Elastic Webbing not only depends on the equipment, but is also closely related to the selection of materials and the optimization of the process. We always adhere to high standards in material selection and use high-quality nylon and imported spandex as the main raw materials. Nylon material is soft and comfortable, suitable for close-fitting products such as belts, while imported spandex gives the webbing excellent elasticity and strength, ensuring that the pattern will not be distorted during stretching. In terms of process, by continuously optimizing weaving parameters such as yarn tension, weaving speed and temperature control, we ensure that each batch of webbing can achieve a consistent pattern effect. During the weaving process, the stability of yarn tension directly affects the clarity of the pattern.

2. Advanced equipment and technical support

In the production of personalized Jacquard Elastic Webbing, the advancement of equipment and the maturity of technology directly affect the accuracy and consistency of the pattern. As an enterprise focusing on the research and development and production of webbing, Jiangyin Baihong Weaving Band has introduced a series of advanced equipment including narrow band knitting machines, jacquard machines, pre-shrinking machines, and warping machines. These equipment not only improve production efficiency, but also provide technical guarantee for the accurate presentation of patterns. Jacquard machines are the core equipment for producing jacquard elastic webbing. They can accurately control the position and tension of each yarn according to the requirements of the design pattern, thereby ensuring the clarity and consistency of the pattern. The jacquard machine is equipped with a high-precision electronic control system, which can achieve high restoration of complex patterns. The use of pre-shrinking machines and warping machines further ensures that the integrity of the pattern will not be affected by shrinkage or deformation during the subsequent processing of the webbing.

3. Strict quality control system

The accuracy and consistency of the pattern not only need to be controlled during the production process, but also need to be ensured through strict quality inspection. Baihong Weaving Band has established a complete quality control system. From the storage of raw materials to the delivery of finished products, each process is strictly inspected.

During the production process, each batch of yarn is tested to ensure that its elasticity and strength meet the requirements. After weaving, the webbing is pre-shrunk to eliminate potential shrinkage problems. The webbing then enters the printing production line and is customized according to the design drawings provided by the customer. After each process, we will conduct corresponding inspections to ensure the accuracy and consistency of the pattern. In the finished product inspection stage, Baihong Weaving Band will conduct a comprehensive inspection according to customer requirements and international standards. For the clarity of the pattern, a high-power magnifying glass is used for detailed inspection; for the elastic performance, a tensile test is performed to verify whether the pattern remains intact after multiple stretching. This strict quality control system ensures that each roll of jacquard elastic webbing can meet the high standards of customers.

4. Personalized customization and customer needs

The production of personalized Jacquard Elastic Webbing not only needs to ensure the accuracy and consistency of the pattern, but also needs to meet the personalized needs of customers. Baihong Weaving Band has demonstrated strong customization capabilities in this regard. Customers only need to provide design drawings or samples to transform them into actual webbing products. Whether it is a complex geometric pattern or a delicate text logo, it can be presented with a high degree of restoration through advanced jacquard technology.

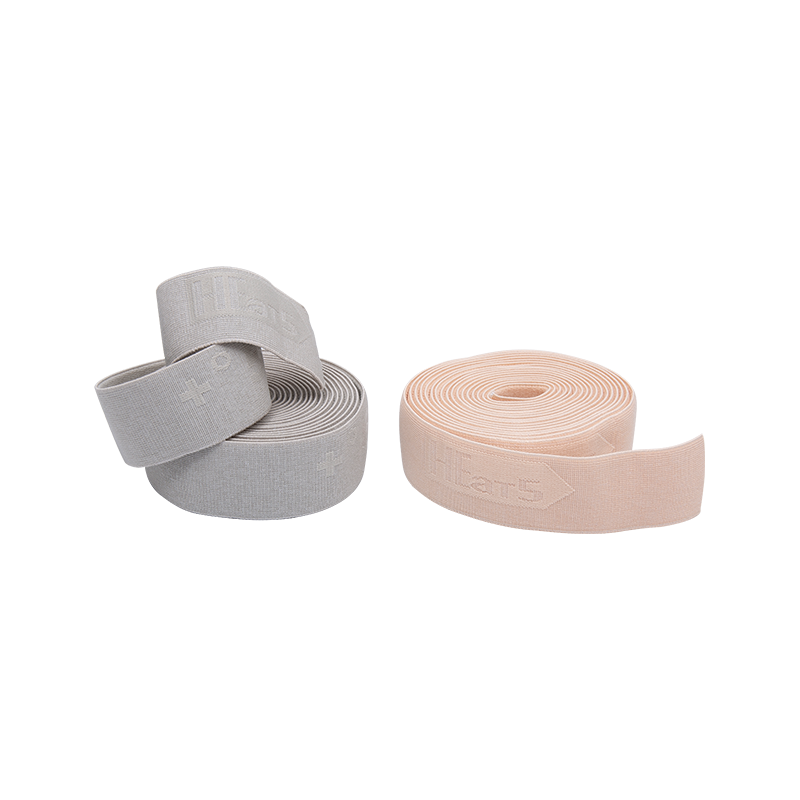

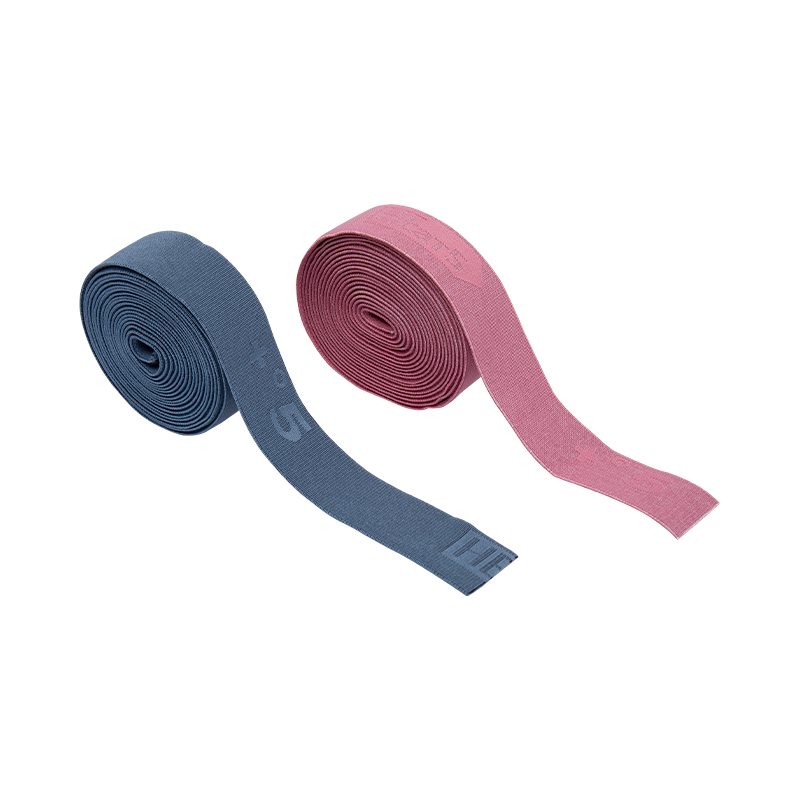

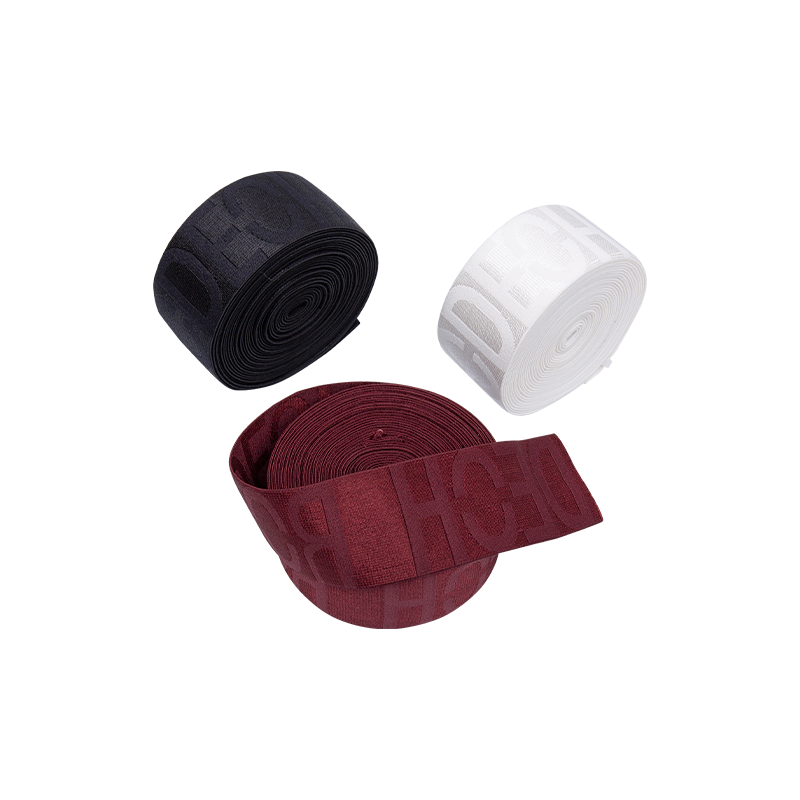

In the field of clothing accessories, customers may need jacquard stretch webbing of specific colors to match the clothing design. Baihong Weaving Band uses precise color matching technology and high-quality dyes to ensure that the color of the webbing is exactly the same as the color card provided by the customer. In the field of sportswear, customers may have higher requirements for the elasticity and durability of the webbing. By optimizing the weaving process and using high-performance materials, we ensure that the webbing still maintains the clarity and integrity of the pattern after multiple stretching.

English

English  русский

русский  Español

Español