We have our own R&D team and testing lab to ensure the quality of the products. In recent years, our company has introduced a series of advanced equipment including Narrow-fabric needle loom ,Jacquard woven machine,pre-shrinking machine,warping machine to improve our production. In addition, we have obtained 100% Okeo-tex certificates. Our products are in line with international standards,and are mainly exported to Europe, America, Japan and other areas around the world.

To maintain excellent service, We’ll take time to deal with each issue, no matter how mundane it may appear to you. Baihong continually strive to be leaders in webbing industry.

-

In the dynamic world of textile manufacturing and fashion design, the demand for materials that combine aesthetic versatility with structural integrity is ever-growing. Designers and manufacturers are constantly seeking ...

READ MORE -

Introduction: More Than Just Function – The Rise of Personalized Fashion In the dynamic world of fashion and self-expression, even the most utilitarian accessories are being reimagined as canvases for individuality. Ente...

READ MORE -

In the rapidly evolving landscape of fashion accessories, the convergence of individual expression and environmental responsibility has become a central theme. Fashion Personalized Shoelaces are no longer just functional...

READ MORE

How to design and customize the pattern and color of polyester jacquard webbing according to customer needs?

1. Understanding customer needs: the starting point of design and customization

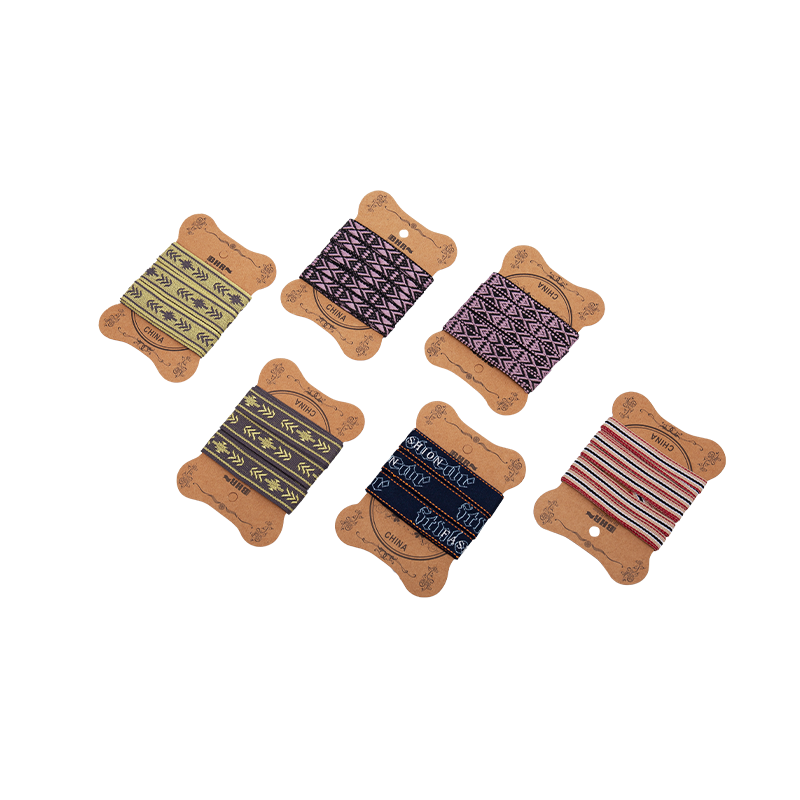

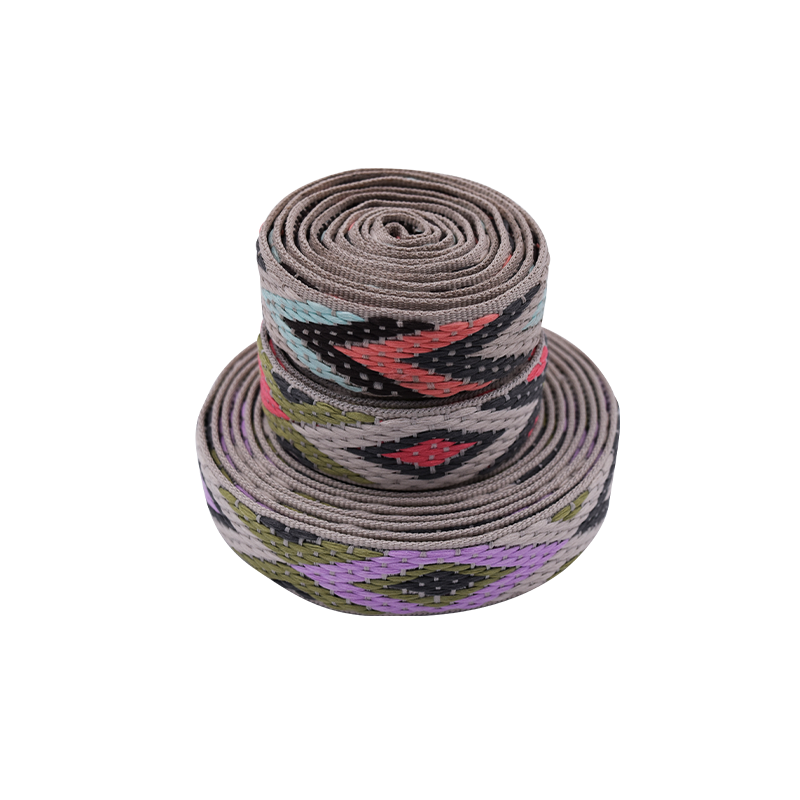

The first step in designing and customizing polyester jacquard webbing is to fully understand the customer's needs. Customer needs may include specific patterns, colors, widths, materials, and end uses. For example, a customer may need a jacquard webbing for high-end luggage shoulder straps, requiring the pattern to be three-dimensional, colorful, wear-resistant, and high tensile strength.

In actual operation, customers can provide design drawings, samples, or simple design concepts. Our R&D team will conduct a preliminary analysis based on this information, and propose a feasible design plan based on the characteristics of polyester jacquard webbing. For example, if the pattern provided by the customer is more complex, the team will recommend the use of Switzerland's advanced computer jacquard machine to ensure the fineness and three-dimensionality of the pattern.

2. Pattern design: from concept to reality

Pattern design is the most creative and challenging part of the polyester jacquard webbing customization process. Baihong Weaving Band's design team not only has rich design experience, but is also equipped with advanced jacquard machine equipment to turn customers' concepts into reality. During the design process, the team will consider the following key factors:

Pattern refinement: The pattern of polyester jacquard webbing usually needs to have a high degree of refinement, especially when used for high-end clothing or luggage. The Swiss computer jacquard machine we use can accurately control the position of each yarn to ensure the clarity and three-dimensional sense of the pattern.

Color matching: Polyester jacquard webbing has good gloss and strong color expression, so the color matching and transition need to be fully considered during design. The R&D team of Baihong Weaving Bandwill accurately match the color according to the color card or Pantone color number provided by the customer to ensure that the final product is consistent with customer expectations.

Pattern adaptability: Different application scenarios have different requirements for patterns. Jacquard webbing used for clothing decoration may require softer colors and delicate patterns, while jacquard webbing used for luggage shoulder straps requires a stronger three-dimensional sense and wear resistance. We will adjust the design style of the pattern according to the end use.

3. Material selection: balancing beauty and functionality

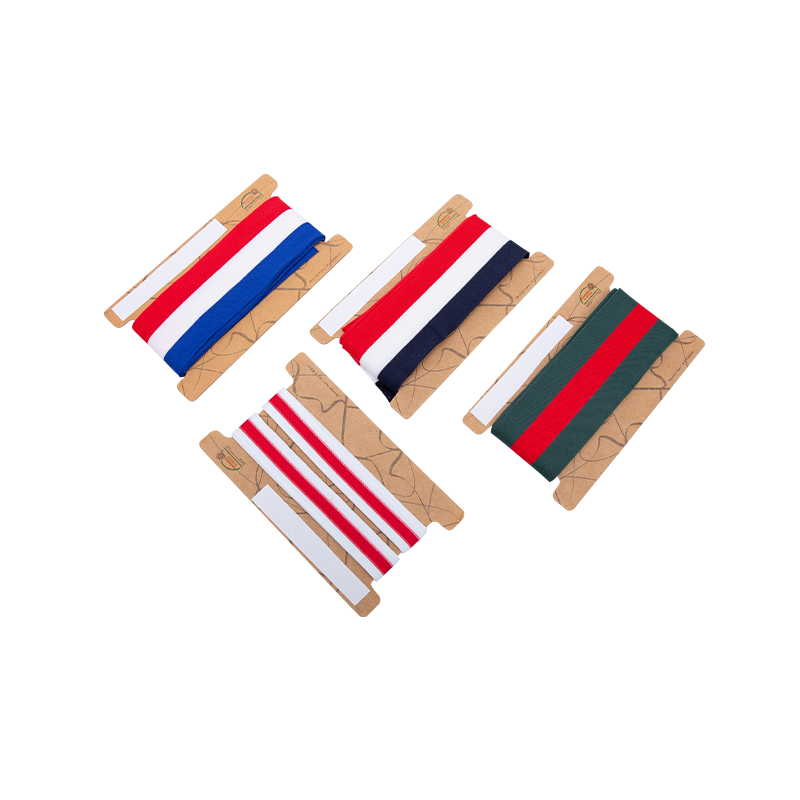

The material selection of polyester jacquard webbing directly affects its appearance and performance. Baihong Ribbon offers a variety of material options, including pure polyester, polyester blends, and other fibers (such as nylon, cotton, linen, etc.). Different materials have different characteristics. For example, polyester is soft and delicate, and has good wear resistance and tensile strength, which is very suitable for high-end luggage shoulder straps or sports backpacks.

During the design and customization process, the team will recommend the most suitable material according to the customer's needs. For example, if a customer needs a jacquard webbing for an outdoor sports backpack, the team may recommend the use of high-strength polyester blended material to ensure the durability of the webbing in harsh environments.

4. Production process: ensure high quality and high efficiency

After the design and material are determined, the next step is to enter the production link. Baihong Ribbon has 4 production lines, including webbing production line, steam heat treatment line and printing production line, with an annual output of up to 60,000,000 meters. The company's introduction of advanced equipment such as narrow cloth knitting machines, jacquard machines, pre-shrinking machines, warping machines, etc., provides a solid guarantee for the production of high-quality polyester jacquard webbing.

During the production process, we strictly follow international standards and conduct corresponding inspections after each process. For example, in the production of jacquard webbing, the team uses Swiss computer jacquard machines to ensure the accuracy of the pattern and the vividness of the color; in the heat treatment process, the steam heat treatment line can effectively improve the feel and stability of the webbing; in the final finished product inspection process, the team will conduct a comprehensive inspection according to customer requirements and international standards to ensure that every meter of webbing meets high quality requirements.

5. Customized service: meet diverse needs

Whether it is a design drawing provided by the customer or a simple design concept, we can respond quickly and provide customized solutions. Customers may need a jacquard webbing with a special width and complex pattern. The Baihong Weaving Band will adjust the equipment parameters and optimize the production process to ensure that the final product fully meets customer needs. We also focus on environmental protection and sustainable development.

English

English  русский

русский  Español

Español